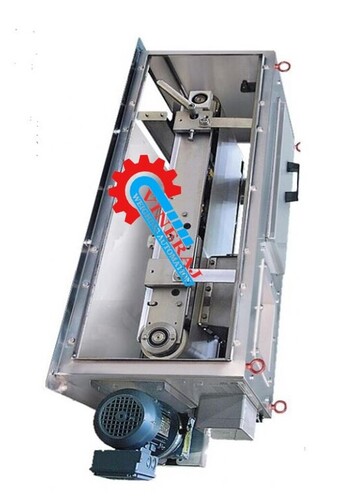

Vibratory Feeder

Vibratory Feeder Specification

- Thickness

- 5 mm

- Features

- Low maintenance, high efficiency, consistent feed rate

- Power Source

- Electric

- Surface Finish

- Powder Coated

- Material

- Mild Steel

- Type

- Vibratory Feeder

- Structure

- Heavy Duty

- Product Type

- vibrator feeder

- Resistant Feature

- Corrosion Resistant

- Load Capacity

- Up to 50 kg

- Voltage

- 220-240 V

- Power

- 80 W

- Speed

- Adjustable

- Usage & Applications

- Feeding granular or powder materials continuously and evenly in industries such as food processing, chemicals, and mining.

Vibratory Feeder Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Vadodara , Gujarat

- Supply Ability

- Unit

- Delivery Time

- Months

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per Client

- Main Domestic Market

- All India

About Vibratory Feeder

We as a prime manufacturer, service provider, and supplier have picked up an unlimited industry involvement in offering a complete array of Vibratory Feeder which is utilized as a part of different manufacturing plants for various applications that aides in controlling the mass taking care of plants and different materials for auxiliary preparing. Our offered array of this item is thought up utilizing incomparable quality electromagnetic or unbalance engine. Our array of Vibratory Feeder is sufficiently adaptable to handle wide assortment of materials and are exceedingly acclaimed among different clients for its simple treatment of hot or rough material.

Features:

- Rust resistance

- High quality

- Simple to pass on material

- Toughness

Versatile Material Handling

Optimized for continuous and uniform feeding, this vibratory feeder is engineered to handle granular or powder materials in diverse sectors such as food processing, chemicals, and mining. The adjustable speed and customizable tray and hopper dimensions ensure flexibility in meeting specific operational demands.

Sturdy, Efficient Design

Fabricated from heavy-duty mild steel with a durable powder-coated finish, the feeder ensures high resistance to corrosion and minimized maintenance needs. Its electromagnetic control system guarantees consistent feed rates, while noise levels remain comfortably below 70 dB for improved workspace conditions.

Customized Solutions for Industry

With options to customize input hopper capacity and feeder tray material, this vibrating unit can be tailored to fit unique industrial requirements. Stainless steel trays are available, further enhancing hygiene and durability for specific applications.

FAQs of Vibratory Feeder:

Q: How does the electromagnetic control benefit the operation of the vibratory feeder?

A: Electromagnetic control provides precise and rapid adjustment of the feed rate, allowing for accurate and continuous material flow. This improves efficiency by adapting to varying process needs without manual intervention.Q: What materials can the vibratory feeder handle effectively?

A: The feeder is suitable for a wide range of granular and powder materials commonly found in food processing, chemical, and mining industries. The customizable tray and hopper allow it to handle material types with different flow properties.Q: Where can the vibratory feeder be installed and used?

A: Designed for both indoor and outdoor environments, the feeders corrosion-resistant structure and operating temperature range up to 50C make it ideal for various industrial locations, including warehouses and processing plants.Q: When is it advantageous to use a vibratory feeder in an industrial process?

A: Vibratory feeders are most beneficial when a continuous, even supply of materials is requiredminimizing manual handling and ensuring consistent processing. This is vital in automated lines where downtime and irregular feed rates can impact overall productivity.Q: What is the process for customizing the tray material and input hopper capacity?

A: Customers can specify requirements for feeder tray material, such as selecting stainless steel for added durability and hygiene. Input hopper capacity is also adjustable according to the volume and type of material to be processed, with design support provided by the supplier.Q: How does the feeders corrosion resistance and powder-coated finish benefit its longevity?

A: Corrosion resistance and powder coating protect the mild steel structure from harsh substances and environments, reducing the risk of wear or damage. This results in lower maintenance needs and a longer operational lifespan for the feeder.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Feeders Category

Inclined Screw Feeder

Price 125000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Product Type : Semi Automatic

Usage : Material handling of any FMCG products like rice, pulses or powder like flour to a hopper at a particular height

Type : Incline and Decline Conveyor

Loss and Weigh Feeders

Price 200000.0 INR / Number

Minimum Order Quantity : 1 Number

Warranty : 1 year

Product Type : Online System Active

Belt Feeder

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Usage : Specialized conveyor systems used to control the flow of bulk materials in a regulated manner

Screw Feeder

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Product Type : Motor operated

Usage : Commonly used in a variety of industries, including food processing, chemical production, and material handling

Type : Screw Conveyor

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry